Uncategorized

How is the Transformer Bushing Testing?

I. Introduction

A. Overview of Transformer Bushing Testing

Transformer bushings play a crucial role in the efficient and safe operation of transformers. Ensuring their reliability is paramount to the overall performance of the electrical power system. In this section, we will delve into the fundamental aspects of transformer bushing testing, emphasizing its significance in preventing failures and ensuring continuous power supply.

B. Importance of Reliable Transformer Bushing Testing Operations

Reliable transformer operations hinge on the quality and functionality of its components, with bushings being a critical part. We will explore how comprehensive testing procedures contribute to the longevity of transformer systems and mitigate potential risks associated with faulty bushings.

C. Key Components and Functions

Understanding the key components and functions of transformer bushings is essential for effective testing. This subsection will provide insights into the construction and role of transformer bushings in electrical systems.

II. Types and Applications

A. Different Types of Transformer Bushings

1. Oil-impregnated paper (OIP) Bushings

Oil-impregnated paper bushings are a common type known for their insulation properties. We will discuss their structure and advantages, shedding light on why they are widely used in certain applications.

2. Resin Impregnated Paper (RIP) Bushings

RIP bushings offer an alternative with distinct characteristics. This section will explore the features and applications that make RIP bushings suitable for specific operational environments.

3. Capacitor-Graded Bushings

Capacitor-graded bushings have unique features catering to specific voltage requirements. We will elaborate on their design and where they find application in the electrical power landscape.

B. Applications Across Industries

1. Power Generation

Transformer bushings play a crucial role in power generation applications. This subsection will discuss the specific requirements and challenges associated with bushings in power generation setups.

2. Transmission and Distribution

In the transmission and distribution of electrical power, different types of bushings serve distinct purposes. This part will provide insights into the applications of transformer bushings in these critical stages of the power supply chain.

3. Industrial Applications

Industries have diverse needs, and transformer bushings are no exception. This section will explore how transformer bushings are tailored for various industrial applications, ensuring compatibility and efficiency.

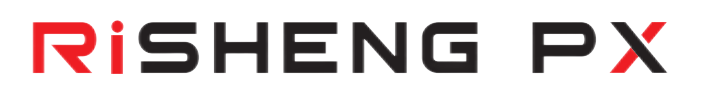

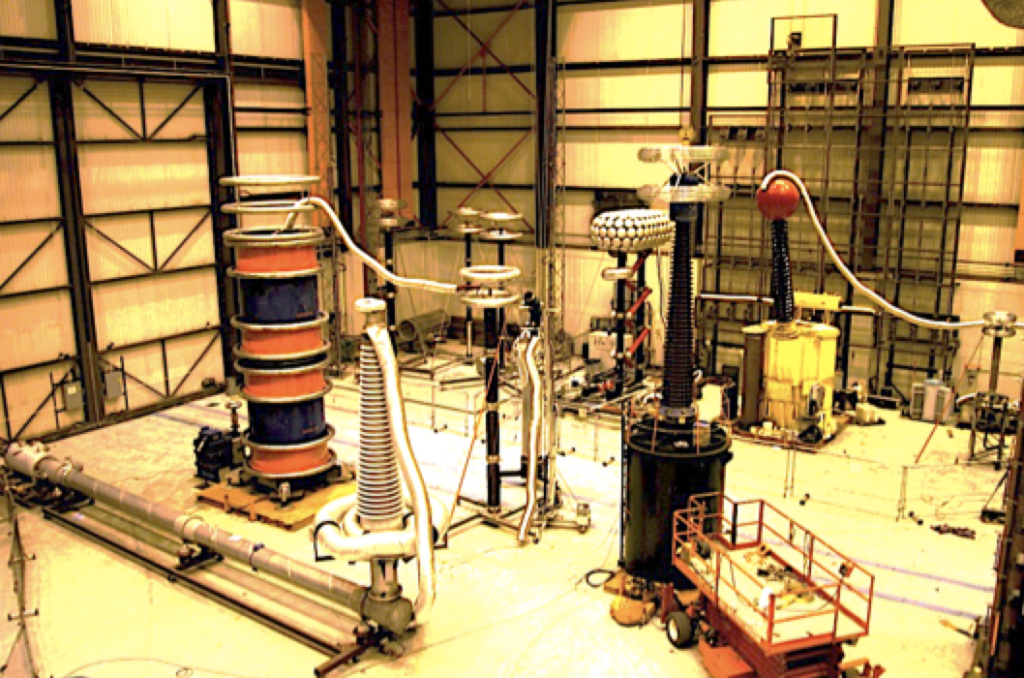

III. Transformer Bushing Testing Methods

A. Overview of Testing

Before delving into specific testing methods, it’s crucial to understand the overall testing procedures involved in ensuring transformer bushing reliability. This section will provide a comprehensive overview of the testing journey.

B. Electrical Testing

1. Power Factor Testing

Power factor testing is a key electrical test for transformer bushings. We will explain the significance of power factor testing and how it aids in identifying potential issues.

2. Partial Discharge Testing

Partial discharge testing is another critical aspect of electrical testing. This subsection will elaborate on its importance and the insights it provides into the condition of transformer bushings.

C. Physical Testing

1. Oil Quality and Analysis

Given the presence of oil in many types of bushings, analyzing oil quality is crucial. This part will delve into the methods used for oil analysis and its role in ensuring the health of transformer bushings.

2. Visual Inspection

Visual inspection is a fundamental aspect of physical testing. This section will outline the visual cues inspectors look for when examining transformer bushings, providing a holistic approach to testing.

IV. Production Process

A. Manufacturing of Transformer Bushings

The production process significantly influences the quality of transformer bushings. Here, we will break down the manufacturing process, from raw materials to the final product, shedding light on key stages and quality control measures.

B. Quality Control Measures

Quality control is integral to delivering reliable transformer bushings. This section will explore the measures taken during production to ensure each bushing meets stringent quality standards.

C. Customization Options for Clients

Understanding the diverse needs of clients, this part will discuss the customization options available for transformer bushings. From size variations to specific material requirements, clients can tailor their orders to meet unique specifications.

V. China as a Hub for Transformer Bushing Manufacturing

A. China’s Role in the Global Transformer Industry

China has emerged as a prominent player in the global transformer industry. We will discuss the factors contributing to China’s dominance and how it has become a hub for transformer bushing manufacturing.

B. Leading Companies in China

Highlighting key players in the Chinese market, this section will introduce reputable companies known for their expertise in producing high-quality transformer bushings.

C. Advantages of Choosing a Chinese Supplier

Choosing the right supplier is crucial for obtaining reliable transformer bushings. Here, we will outline the advantages of opting for a Chinese supplier, including cost-effectiveness, advanced technology, and vast production capabilities.

VI. Choosing the Right Supplier

A. Factors to Consider

1. Company Reputation

The reputation of a supplier speaks volumes about the quality of their products. In this section, we will discuss how a supplier’s reputation should be a primary consideration for potential buyers.

2. Quality Standards and Certifications

Ensuring that a supplier adheres to international quality standards is paramount. We will explore the certifications and standards buyers should look for when selecting a transformer bushing supplier.

3. Customization Services

Customization plays a crucial role in meeting specific project requirements. This part will delve into the importance of customization services and how they contribute to the success of a project.

B. Questions to Ask Potential Suppliers

1. Production Capacity

Understanding the supplier’s production capacity is essential for timely project completion. This section will guide buyers on the questions to ask regarding production capabilities.

2. Lead Times

Timely delivery is critical in the electrical power industry. Here, we will discuss the importance of lead times and how buyers can ensure timely delivery by discussing this aspect with potential suppliers.

3. Quality Assurance Measures

Quality assurance is central to the reliability of transformer bushings. This part will outline the questions buyers should pose to suppliers regarding their quality control measures.

4. Pricing and Cost Structure

Price considerations are integral to any procurement decision. We will explore how buyers can navigate pricing discussions and understand the cost structure offered by potential suppliers.

VII. International Buyer’s Guide

A. Key Considerations for International Buyers

International buyers face unique challenges when sourcing transformer bushings. This section will provide a comprehensive guide on considerations such as shipping logistics, communication, and cultural differences.

B. Overcoming Language and Communication Barriers

Effective communication is key to successful international transactions. Here, we will discuss strategies for overcoming language barriers and ensuring clear communication between international buyers and Chinese suppliers.

C. Understanding and Navigating Cultural Differences

Cultural differences can impact business interactions. This subsection will provide insights into understanding and navigating cultural nuances when dealing with Chinese suppliers, fostering positive and productive relationships.

VIII. FAQ Tips for Buyers

A. Commonly Asked Questions and Answers

1. How to Ensure Product Quality?

Ensuring product quality is a top priority for buyers. This section will address common concerns and provide tips on how buyers can ensure the quality of transformer bushings.

2. What Certifications Should Buyers Look For?

Certifications are indicative of a supplier’s commitment to quality. We will discuss the certifications buyers should prioritize when selecting a transformer bushing supplier.

3. Is Customization Possible?

Buyers often have specific requirements for their projects. This part of the FAQ Tips will elaborate on the possibilities and advantages of customization when sourcing transformer bushings, empowering buyers to tailor products to their exact needs.

4. Pricing and Cost Breakdown

Understanding the pricing structure is vital for budgetary considerations. Here, we will break down the typical cost components associated with transformer bushings and guide buyers on how to interpret pricing details provided by suppliers.

5. How to Handle Shipping and Logistics?

Navigating the complexities of shipping and logistics is crucial for international buyers. This section will provide practical tips on how buyers can coordinate with suppliers to ensure smooth transportation and timely delivery.

IX. Conclusion

A. Recap of Transformer Bushing Testing Importance

In this concluding section, we will summarize the key points discussed throughout the article, emphasizing the importance of thorough testing in ensuring the reliability and longevity of transformer bushings.

B. Choosing the Right Supplier for Long-Term Success

Highlighting the critical role of selecting the right supplier, we will reinforce the factors buyers should consider when making this crucial decision, emphasizing the long-term success of their projects.

C. Final Thoughts on the Transformer Bushing Industry

Concluding with insights into the dynamic and evolving nature of the transformer bushing industry, this part will provide final thoughts and reflections on the advancements, challenges, and future trends in transformer technology.